Tel: +31 6 535 77001

Email: [email protected]

Technology

Revolutionary

Cooling

Technology

Securing longer shelf life &

increasing safety of fresh food products

Slurry Ice for Rapid Chilling

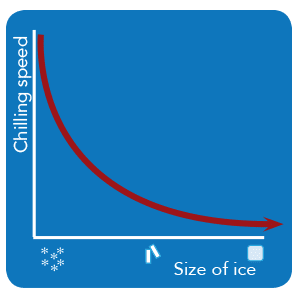

Thor Ice slurry ice is a low temperature “slush” made of thousands of crystals created by scraping the inside of a Thor Ice generator. The size of each ice crystal is thousands of times smaller than a small chunk of flake ice. The small slurry ice particle results in greater heat transfer than any other type of ice.

The spherical crystals in the ice particles exhibit good flow properties which allows for easy circulation through conventional pumps and piping. The small sized crystals flow into crevices and provide greater surface contact and, hence, much faster cooling rates than other traditional forms of ice cooling (flake, block, shell, etc.).

Slurry ice can be produced with different density levels, ranging from 10% to over 90%. These different densities produce different chilling efficiencies, making this technology applicable to different food groups and different product types.

Slurry ice delivers from 10 to 40 times more chilling capacity than chilled water. For example, one litre of 20% slurry replaces over 20 litres of chilled water.

Thor Ice Concept

Thor Ice has developed a unique set of technologies for producing, storing, and distributing slurry ice. These technologies allow efficient and complete chilling of fresh products like fish, poultry, and meat, throughout the entire food value chain: from processing through distribution to consumption.

With the Thor Ice technology, slurry ice can be controlled and distributed more easily and productively than ever. That is why the technology has proven to be more effective than any other chilling method — cold air, flake ice, chilled seawater, and traditional ice cubes.

The main goal of the Thor Ice technology is to preserve the quality of fresh materials by reducing flesh tearing and by stabilising and controlling the growth of harmful bacteria (ie., E. coli or Campylobacter). In fisheries the Thor Ice technologies also reduce the breakdown and effect of krill, preserve freshness, and extend shelf life of all products.

Rapid chilling with slurry ice gives food producers an opportunity to handle food easier during processing, to reduce labor, waste disposal and energy costs.

Patented Modular Technology

Thor Ice chilling technology enables for more economical operations and improves meat texture – another important quality parameter as well.

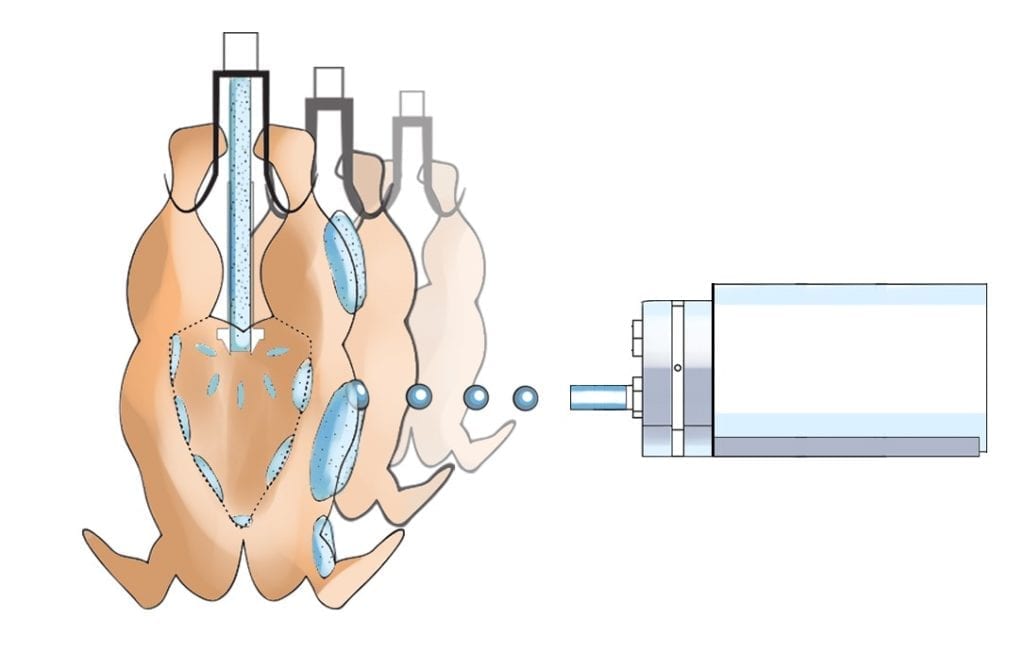

The Thor Ice technology platform is modular. It is designed to complement existing chilling to yield more efficient results. By using special spray nozzles, called IceGuns®, slurry ice is sprayed on the inside or the outside of the product as it passes through production.

The patented IceGuns® are designed to spray slurry ice at the correct concentration, time and temperature to maximise cooling efficiency. The number of IceGuns® and their position are adapted to individual processes and programmed in a way that they provide target results.

Benefits of Using Thor Ice Technology

Applying Thor Ice technology can have significant effect on the quality of the product as well the cost of chilling. It is possible to calculate investment payback directly from the yield and energy savings.

Other benefits, such as extended shelf life, reduced bacteria growth and others, are difficult to calculate and put numbers on, even though they are of great importance.

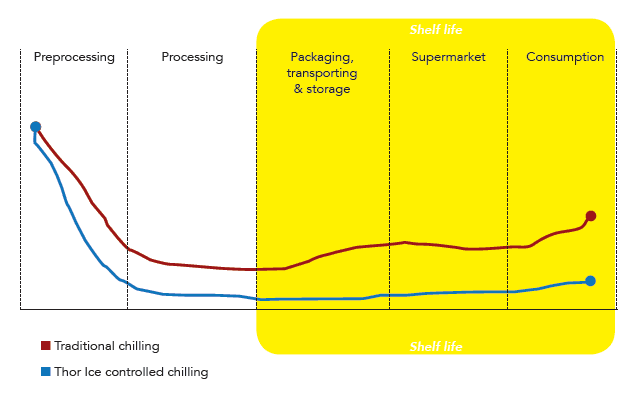

Shelf life is one of the most important factors in the decision to consider Thor Ice technology since, for many processors, one day in improved shelf life alone will return investment in less than a year.

Rapid chilling of fresh material as soon as possible after slaughtering or harvesting and keeping the entire production process chilled is essential to preserving freshness of food products. By applying Thor Ice technology, using controlled rapid chilling, shelf life can be extended significantly.

Effective cooling is the key to preserving product quality, reducing bacteria growth, ensuring food safety, extending shelf life, and reducing food waste.

Fewer bacteria means longer shelf life, preserved quality, and better taste and appearance. From a food safety point of view, risk of human diseases is reduced with rapid and timely chilling, which is the main goal of Thor Ice chilling technology. On the other hand, customers enjoy well preserved, tasty, and healthy products.

Substantial energy savings can be accomplished with controlled slurry ice depending on the methods used. With Thor Ice slurry ice technology, the need for additional air chilling is reduced which is directly linked to the lower energy consumption.

Producers can save considerably when using slurry ice for chilling as an upgrade for water chilling and dipping methods. Furthermore, a 1% drip reduction could save large amounts every year, depending on the production volume. In poultry production, Thor Ice system delivers over 90% savings in water use when combined with air chilling compared to when water chilling methods are used.

Cutting operational costs by preventing waste of energy, water, and raw material resources is a solid ground for stable operations in food processing. Thor Ice technology enables increased product quality and environmentally friendly production can only bring in more customers, while management is successfully meeting challenges in today’s economy.

Regardless of the chilling method used today, whether it is dipping, air chilling, and/or combined air and water chilling, Thor Ice’s rapid slurry ice chilling technology can be used with any current method. The main advantage is that Thor Ice solutions are plugged into the existing system in a way that works well with the existing chilling method, while enhancing the chilling results in a timely and programmed manner in places where lower temperature is required. Installation does not require any down time and therefore does not disrupt ongoing operations. As a bolt-on system, it utilises existing buildings, reducing the need for huge investments and new buildings, that are in themselves a major contribution to CO2 emissions.

With the existing methods for chilling, it is very hard or almost impossible to make physical changes when more chilling space is needed. Building a larger chilling chamber with all included is a large investment and can in some instances take a long time. In contrast to that, Thor Ice slurry ice chilling solutions cost much less and can be installed without interrupting ongoing operations. As a bolt-on system, it makes it possible to continue to use existing infrastructure and buildings, significantly reducing the massive carbon footprint involved in new construction.

Payback that can be calculated directly is yield and energy savings. Other benefits, such as extended shelf life, reduced bacteria growth, and others, are difficult to put numbers on, even though they are of great importance. Shelf life is one of the most important factors in a decision to invest in a system like this. Interested companies have mentioned that 1 day in increased shelf life would be enough to pay back the investment in less than 1 year. Increased throughput and shorter workdays, as an advantage of Thor Ice technology, make it possible to increase production.

Increased environmental awareness and strict legislations are pressuring food processors to adjust to more environmentally friendly practices and to reduce their costs. Thor Ice’s products and services have been designed to address these issues. Significantly, Thor Ice products have led to increased COP over traditional methods, at the same time resulting in chilling to temperatures below freezing using slurry ice machines and controlled slurry ice to chill a product before freezing, requiring less energy to operate.