Tel: +31 6 535 77001

Email: [email protected]

Products

System Components

The cornerstone of the Thor Ice chilling technology is a unique, patented product called the IceGun®. The IceGun® is designed to manage, distribute, and control slurry ice onto a product as it passes on the processing lines. The IceGun® cylinder combines the right concentration and volume of ice that is applied onto the product. The concentration, volume, shooting angle, rate, and dwell time can be adjusted for the maximum cooling benefits for each position along the line. This can be increased or decreased according to the results obtained. We call this programmed chilling. The number of IceGuns® and their position will vary in order to adapt to each user’s needs and wishes.

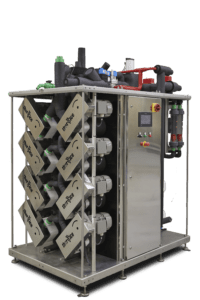

Our slurry ice machines come in different sizes to meet customer needs and environmental regulations.

- Durable, efficient, in-house designed generators

- PED certified generators

- High COP ratio available

- Eco friendly

- From 5% to over 90% ice concentration

Isolated slurry ice storage tanks with a built-in agitator system and controls, securing consistency and quality of the slurry ice at any given time.

For over a decade, Thor Ice has been a supplier of reliable and efficient slurry ice machines, generators, and complete systems for food processing where chilling is crucial for an extended shelf life of products. The Thor Ice slurry ice machines range from smaller installations intended for boats or operations on land to scalable industrial series for land-based applications and large installations at sea.

| Model | Capacity (kW) | Power (kW) | Litres/Hour | Voltage | WxDxH (cm) | Frequency (Hz) |

| S-50 | 1.75 | 0.85 | 38-240 | 24/230 | 70/25/50 | 50/60 |

| S-100 | 3.50 | 1.75 | 80-500 | 230/400 | 70/25/50 | 50/60 |

| S-200 | 6.50 | 3.25 | 155-898 | 400 | 90/30/60 | 50/60 |

| S-300 | 9.00 | 4.50 | 233-1484 | 400 | 120/30/60 | 50/60 |

| S-400 | 11.50 | 7 | 310-2000 | 400 | 150/40/60 | 50/60 |

| S-800 | 23 | 11.5 | 620-4000 | 400 | 50/60 | |

| S-1600 | 46 | 23 | 400 | 50/60 |

- We design and manufacture slurry ice systems and machines for chilling of raw material in all major food processing industries.

- Thor Ice machines are developed by, and in close cooperation with, Icelandic fishermen and fish processing companies, institutions, and scientists.

- We offers sizes from the smallest on-board machines on the market to large eco-friendly industrial units.

- Thor Ice expertise and know-how in chilling of fresh material secures longer shelf life of products.

Unique Thor Ice measuring tools are used to access the chilling efficiency, both before and after the implementation of a Thor Ice system. The sophisticated measuring tools are used to evaluate the existing chilling process. The data from these measurements is used to provide a solution to enhance the chilling process.

Probes show the temperature around and inside the bird, covering the areas that are deepest and hardest to reach. The instruments also show the thermal effect of the existing system, taking into consideration the temperature, effect of air, water, and ice. This is important in order to be able to program the chilling in a way that would not freeze or damage the surface, wings, and skin, while targeting the breasts and legs that take the longest to chill.

Heart of Thor Ice technology is ongoing monitoring of temperature movements throughout the processing and post-processing stages. That way, the chilling method is constantly improved and adjusted to individual clients’ needs. 24/7 temperature tracking will signal potential errors in chilling.

Free On-Site Measurement

We offer potential clients a free measurement and budgeting estimate for a solution that meets their specific needs.

Please contact us for more information.